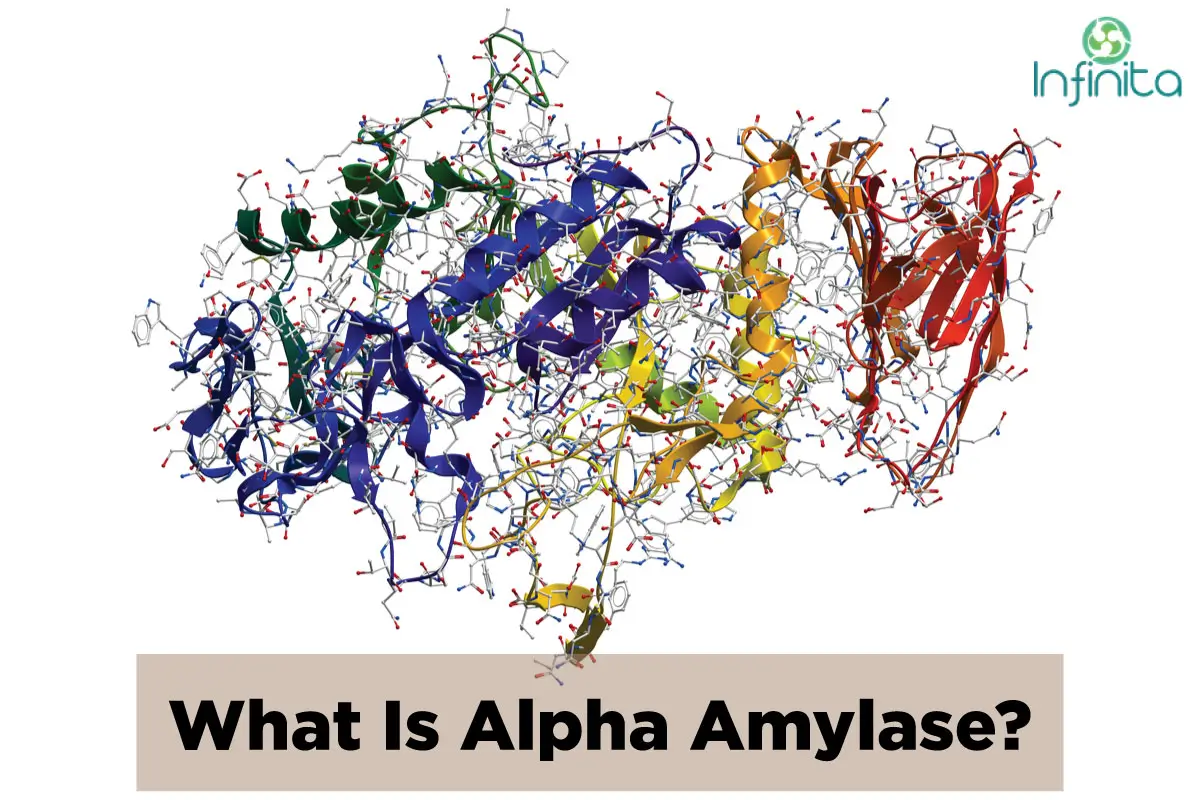

What Is Alpha Amylase Enzyme And Its Uses?

Amylase, any member of a category of enzymes that catalyse the chemical reaction (splitting of a compound by addition of a water molecule) of starch into smaller saccharide molecules like maltose (a molecule composed of two glucose molecules). Two classes of amylases, denoted alpha and beta, dissent within the method they attack the bonds of the starch molecules. Alpha amylase is widespread among living organisms.

Industrial Application Of Alpha Amylase Enzyme

1. Starch Conversion

The most widespread applications of alpha amylases are in the starch industry, which is used for starch hydrolysis in the starch liquefaction process that converts starch into fructose and glucose syrups. The supermolecule conversion of all starch includes gelatinization, that involves the dissolution of starch granules, thereby forming a viscous suspension; phase change, that involves partial chemical reaction and loss in the body; and saccharification, involving the assembly of aldohexose and disaccharide via any reaction. Initially, the alpha amylase of eubacteria amyloliquefaciens was used however it’s been replaced by the alpha amylase enzyme of eubacteria stearothermophilus or eubacteria licheniformis.

The enzymes from the eubacteria species are of interest group for large-scale biotechnological processes because of their exceptional thermostability and since economical expression systems are offered for these enzymes.

2. Detergent Industry

Detergent industries are the first customers of enzymes, in terms of each volume and price. The use of enzymes in detergents formulations enhances the detergents ability to get rid of robust stains and creating the detergent environmentally safe. Amylases are the second style of enzymes employed in the formulation of protein detergent, and ninetieth of all liquid detergents contain these enzymes.

These enzymes are utilised in detergents for laundry and automatic lavation to degrade the residues of starchy foods like potatoes, gravies, custard, chocolate, etc. to dextrins and alternative smaller oligosaccharides. Amylases have activity at lower temperatures and base-forming pH scale, maintaining the required stability below detergent conditions and therefore the aerophilous stability of amylases is one among the foremost vital criteria for their use in detergents wherever the laundry surroundings are incredibly oxidising. Removal of starch from surfaces is also important in providing a whiteness benefit since starch can be an attractant for many types of particulate soils. Examples of amylases employed in the detergent business are derived from eubacteria or Aspergillus.

3. Fuel Alcohol Production

Ethanol is the most utilised liquid biofuel. For ethanol production, starch is the most used substrate due to its low price and easily available raw material in most regions of the world. In this production, starch has to be solubilised and then submitted to two enzymatic steps in order to obtain fermentable sugars.

The bioconversion of starch into alcohol involves natural process and saccharification, wherever starch is reborn into sugar using an amylolytic microorganism or enzymes like alpha amylase, followed by fermentation, where sugar is converted into ethanol using an ethanol fermenting microorganism such as yeast Saccharomyces cerevisiae. The production of ethanol by yeast fermentation plays an important role in the economy of Brazil. In order to obtain a new yeast strain that can directly produce ethanol from starch without the need for a separate saccharifying process, protoplast fusion was performed between the amylolytic yeast Saccharomyces fibuligera and S. cerevisiae. Among microorganism, α-amylase obtained from thermos flask resistant microorganism like true bacteria licheniformis or from built strains of Escherichia coli or Bacillus subtilis is used during the first step of hydrolysis of starch suspensions.

4. Food Industry

Amylases are extensively utilised in processed-food business like baking, brewing, preparation of digestive aids, production of cakes, fruit juices and starch syrups. The α-amylases are wide employed in the baking business. These enzymes can be added to the dough of bread to degrade the starch in the flour into smaller dextrins, which are subsequently fermented by the yeast. The addition of α-amylase to the dough results in enhancing the rate of fermentation and the reduction of the viscosity of dough, resulting in improvements in the volume and texture of the product.

Moreover, it generates extra sugar within the dough, which improves the taste, crust colour and toasting qualities of the bread. Besides generating possible compounds, α-amylases also have an anti-staling effect in bread baking, and they improve the softness retention of baked goods, increasing the shelf life of these products. Currently, a thermostable maltogenic enzyme of eubacteria stearothermophilus is employed commercially within the bakehouse business. Amylases are also used for the clarification of beer or fruit juices, or for the pre-treatment of animal feed to improve the digestibility of fibre.

5. Textile Industry

Amylases are used in the textile industry for the de-sizing process. Sizing agents like starch are applied to yarn before material production to make sure a quick and secure weaving method. Starch is a very attractive size, because it is cheap, easily available in most regions of the world, and it can be removed quite easily. Starch is later far from the woven material in an exceedingly wet-process within the textile finishing business. De-sizing involves the removal of starch from the material that is the strengthening agent to forestall breaking of the warp thread throughout the weaving method. The α-amylases take away by selection the dimensions and don’t attack the fibres. Amylase from true bacteria stain was utilised in textile industries for quite a very long time.

6. Paper Industry

The use of α-amylases within the pulp and paper business is for the modification of starch of coated paper, i.e. for the assembly of low-viscosity, high molecular weight starch. The coating treatment serves to make the surface of paper sufficiently smooth and strong, to improve the writing quality of the paper. During this application, the consistency of the natural starch is just very high for paper size and this may be altered by part degrading the chemical compound with α-amylases during a batch or continuous processes. Starch could be a sensible filler agent for the finishing of paper, improving the quality and erasability, besides being a good coating for the paper. The size enhances the stiffness and strength in the paper.

Conclusion

The use of α-amylase in starch-based industries has been prevalent for many decades and a number of microbial sources exist for the efficient production of this enzyme, but only a few chosen strains of fungi and bacterium meet the factors for business production.

The search for new microorganisms that can be used for amylase production is a continuous process. More recently, several authors have given sensible leads to developing α-amylase purification techniques, that modify applications in pharmaceutical and clinical sectors that need high purity amylases.

Infinita Biotech is one of the best enzyme manufacturer in Gujarat, India. To learn more about enzymes and its uses in different sectors visit Infinita Biotech.

Summarize this Article with AI

Summarize this Article with AI