Introduction

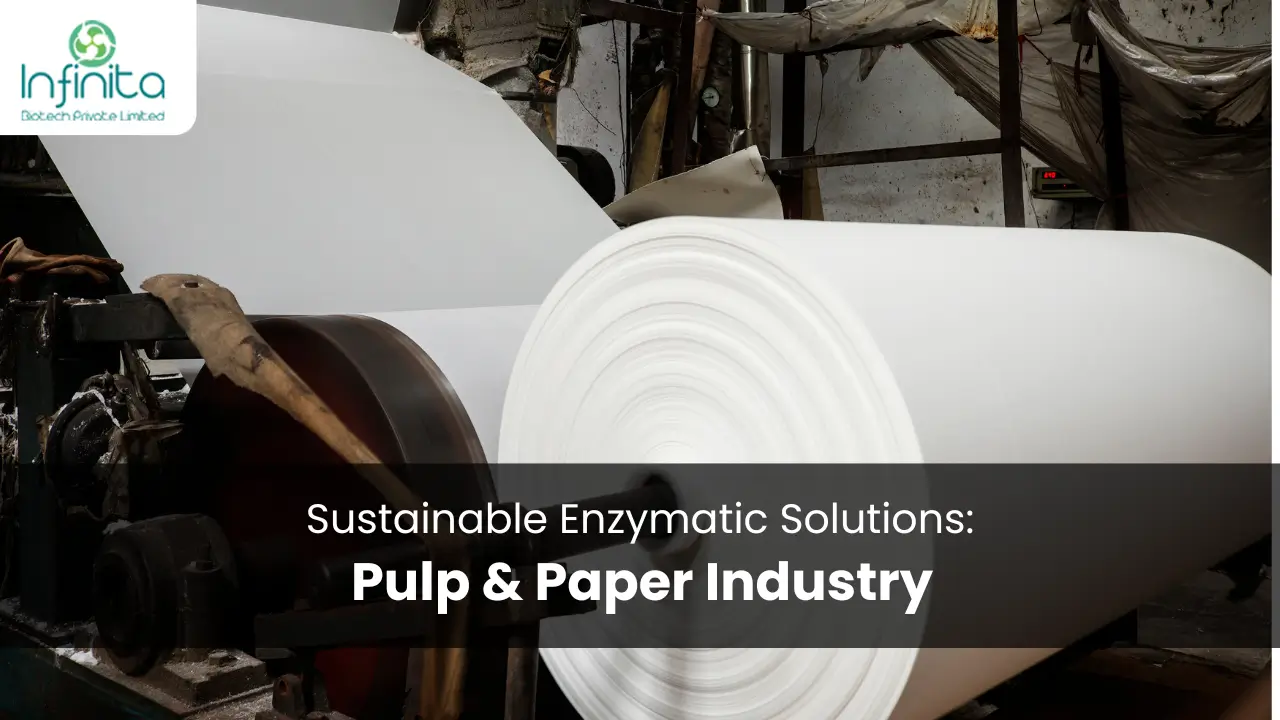

The pulp and paper industry, a vital sector of the global economy, is also among the most environmentally impactful. This industry is not only a significant water consumer but also a major contributor to water pollution.

The introduction of enzymatic solutions presents a promising avenue towards sustainability, offering a greener alternative to traditional chemical processes.

The Environmental Impact of Pulp and Paper Industry

The industry is notorious for its substantial waste generation, leading to severe water pollution. The discharge of organo-chlorine compounds, a byproduct of the bleaching process, poses a significant threat to both aquatic and terrestrial ecosystems.

These compounds are known for their potential to cause genetic and reproductive harm in various species, including humans.

The Rise of Green Technology in Paper Manufacturing

In response to these environmental challenges, the industry has been shifting towards more sustainable practices. Biotechnology, particularly the use of enzymatic solutions, has emerged as a key player in this transformation.

These eco-friendly alternatives not only reduce the industry’s environmental footprint but also offer economic benefits.

Understanding Xylanases and Laccases

Central to this green revolution are enzymes like xylanases and laccases. Xylanases, primarily found in bacteria and fungi, play a crucial role in breaking down hemicelluloses, a major component of plant cell walls.

Laccases, on the other hand, are known for their ability to oxidize phenolic compounds, making them invaluable in the bleaching process.

Enzymatic Bleaching: A Sustainable Approach

Enzymatic bleaching, utilizing these enzymes, offers a sustainable alternative to traditional chlorine-based methods. This approach not only reduces the release of harmful chemicals but also lowers energy consumption and production costs.

Applications of Enzymes in Pulp and Paper Industry

Enzymes have diverse applications in the industry, from improving the pulping process to enhancing paper quality. They play a pivotal role in reducing the need for harsh chemicals and energy, thereby contributing to a more sustainable production process.

This application of enzymes in the pulp and paper industry is integral to advancing eco-friendly practices, ensuring a greener future for the sector.

Case Studies and Success Stories

Several paper mills worldwide have successfully integrated enzymatic solutions into their processes. These case studies highlight significant reductions in environmental impact and operational costs, showcasing the practical benefits of these green technologies.

Challenges and Limitations

Despite their advantages, enzymatic solutions face technical and economic challenges. The industry must address these limitations to fully harness the potential of these green technologies.

Future Prospects and Innovations

The future of enzymatic solutions in the pulp and paper industry looks promising. Ongoing research and innovation are likely to lead to the discovery of new enzymes and applications, further advancing the industry’s sustainability goals.

Conclusion: The Future of Biotech in Cosmetics

Enzymatic solutions in the pulp and paper industry represent a significant step towards a more sustainable future. By embracing these eco-friendly technologies, the industry can reduce its environmental impact while maintaining economic viability.

The continued evolution and adoption of these solutions are crucial for the industry’s sustainable development.

FAQs: Enzymatic Solutions in Pulp and Paper Industry

What are enzymatic solutions in the pulp and paper industry?

Enzymatic solutions involve the use of enzymes, like xylanases and laccases, to facilitate various processes in paper manufacturing, such as pulping, bleaching, and deinking, in a more environmentally friendly manner.

How do enzymatic solutions benefit the environment?

They reduce the industry’s reliance on harmful chemicals and decrease water pollution and energy consumption, contributing to a more sustainable and eco-friendly production process.

Are enzymatic solutions cost-effective?

While the initial investment may be higher, enzymatic solutions can lead to long-term cost savings through reduced chemical and energy usage.