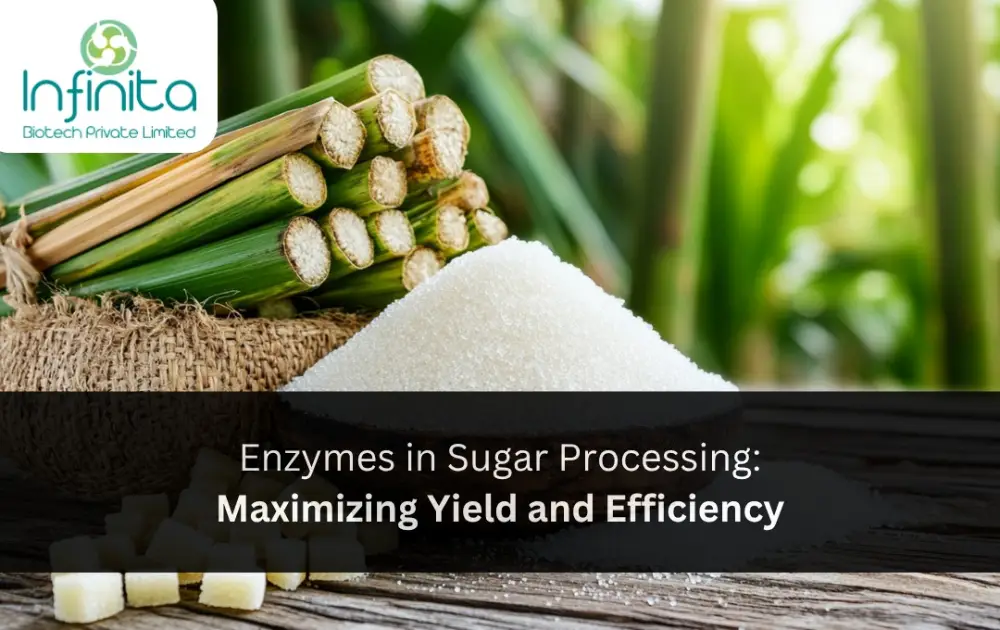

In the modern food and beverage industry, efficiency and sustainability are no longer optional — they’re essential. In this context, enzymes have emerged as powerful tools in sugar processing, transforming traditional production methods into more cost-effective and eco-friendly operations. From improving juice extraction to enhancing refining stages, enzymes help optimize yield, reduce energy consumption, and improve the overall quality of sugar.

What Is Sugar Processing?

Sugar processing refers to the conversion of raw materials — such as sugarcane or sugar beet — into refined sugar. This multi-step process includes extraction, clarification, evaporation, crystallization, and drying. Each of these steps can be enhanced by enzymatic intervention to improve efficiency and minimize losses.

Traditionally, sugar mills relied on physical and chemical methods, but these can be energy-intensive and generate waste. Enzymes offer a cleaner and more targeted alternative.

Role of Enzymes in Sugar Processing

Enzymes are biological catalysts that accelerate specific reactions. In sugar processing, several classes of enzymes are used to improve specific stages:

1. Cellulases and Hemicellulases

These enzymes break down plant cell walls, helping to release more sucrose from sugarcane or beet fibers. This results in:

- Higher juice recovery

- Reduced bagasse waste

- Better extraction from lower-quality raw material

2. Amylases

If starch contamination is present (especially in beet processing), amylases are used to hydrolyze starch into simple sugars. This prevents filtration problems and avoids haze in the final product.

3. Dextranases

Dextran, a sticky polysaccharide formed by microbial activity, increases viscosity and hampers filtration. Dextranase breaks it down, improving flow and reducing equipment wear.

4. Invertases

These enzymes convert sucrose into glucose and fructose, which is useful in the production of invert sugar syrups — commonly used in confectionery and soft drinks.

Key Benefits of Enzymes in Sugar Processing

Using enzymes in sugar production offers measurable advantages across performance, quality, and sustainability:

✔ Increased Yield

Enzymatic treatment helps extract more fermentable sugars from raw materials, especially from damaged or immature crops. This directly translates into improved profitability.

✔ Improved Process Efficiency

Enzymes reduce viscosity and improve the flow of juices and syrups. This enhances filtration, reduces energy needs for evaporation, and leads to faster processing times.

✔ Reduced Chemical Dependency

Enzymes minimize the need for synthetic clarifying or bleaching agents, supporting cleaner labels and reducing environmental impact.

✔ Equipment Longevity

Lower viscosity and cleaner flows reduce scale formation, corrosion, and blockages — minimizing maintenance needs and prolonging equipment life.

Applications Across Sugar Types

Whether producing white crystalline sugar or value-added syrups, sugar processing benefits from enzymatic solutions at every level:

- Cane Sugar Mills: For better juice extraction and clarification

- Beet Sugar Plants: To remove starch and improve filterability

- Refineries: To produce high-purity syrups with improved stability

- Bioethanol Plants: For maximum sugar release before fermentation

Customized enzyme formulations can be tailored to the specific conditions and raw material types of each processing facility.

Sustainability Through Biotechnology

One of the most significant contributions of enzymes to sugar processing is their alignment with sustainable production goals. By reducing energy use, minimizing effluent generation, and enhancing yield from the same input, enzymatic processing supports:

- Lower carbon footprints

- Less water consumption

- Fewer processing chemicals

For sugar manufacturers looking to meet environmental standards or consumer demands for sustainable sourcing, enzymes offer a natural, high-performance solution.

Conclusion

As the sugar industry evolves to meet global demands for efficiency, quality, and sustainability, enzymes are becoming central to modern sugar processing. Their ability to boost yield, cut energy use, and streamline production makes them an indispensable part of any progressive sugar manufacturing operation.

By incorporating enzyme-based biotechnology into sugar refining, processors can not only stay competitive but also lead the shift toward cleaner, smarter production practices.

Summarize this Article with AI

Summarize this Article with AI