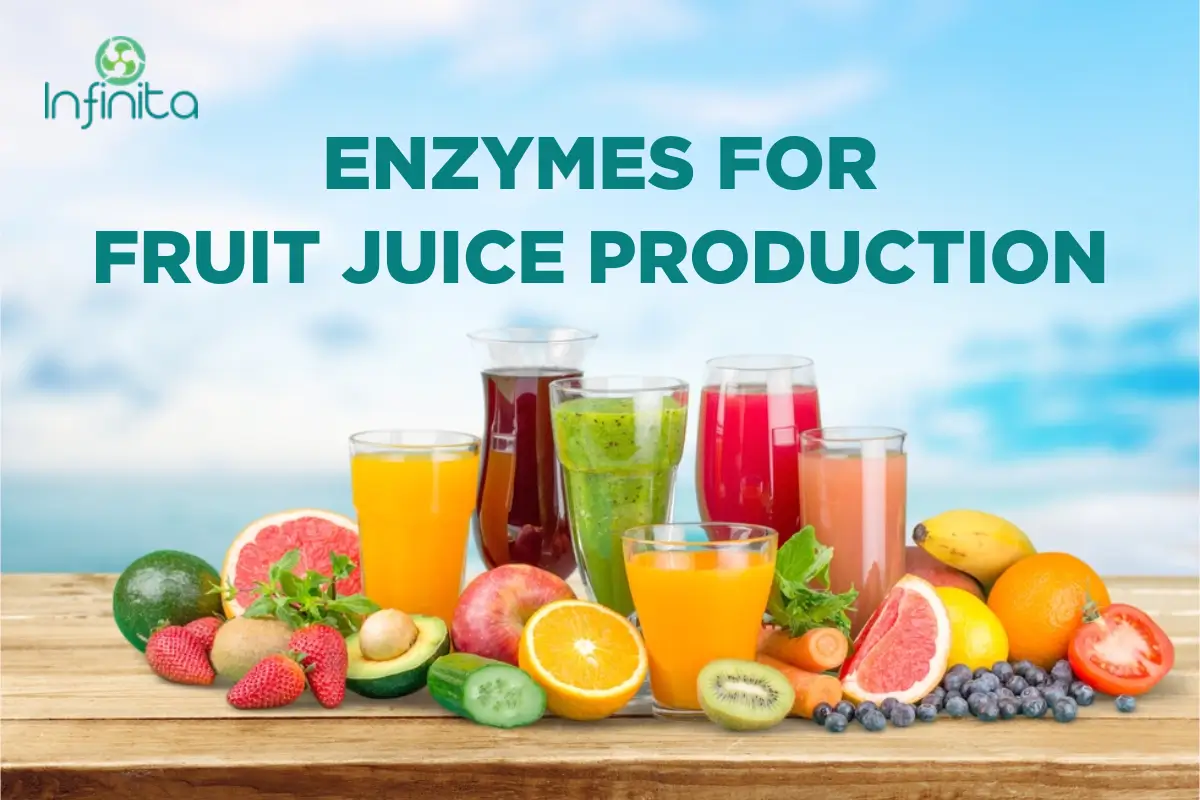

Common Enzymes In Fruit Juice Production

The demand for fruit juices is increasing day by day as a result of increasing health awareness among the people. Most of the juice extraction processes are not producing satisfactory quantity and quality of juices. Enzymatic extraction of juices results in higher yield. The enzymes used are mainly pectinase, cellulase, hemicellulose, etc. Apart from promoting juice extraction, enzyme addition increases the release of various phenolic and other nutritionally important components in the juice. Juice appearance is also improved by enzymatic clarification. Juice quality in terms of reduced viscosity decreased turbidity, and improved filterability is also improved. Enzymes are also used for debittering of citrus fruit juices and in preventing darkening of juices.

The post-harvest shelf life of maximum fruits and vegetables is very limited due to their perishable nature. In India, more than 20–25% of fruits and vegetables are spoiled before utilisation. Despite being the world’s second largest producer of fruits and vegetables, India process only 1.5% of the total fruits and vegetables produced.

Fruits are mainly water (75–90%), most located in vacuole causing turgor to the fruit tissue, and fruit juice is prepared by mechanically squeezing or macerating fresh fruits without the application of heat or solvents. Fruit cell wall consists of crystalline cellulose microfibrils embedded in an amorphous matrix of pectin and hemicelluloses. Juice is composed of water; soluble solids (sugars and organic acids); aroma and flavour compounds; vitamins and minerals; pectic substances; pigments; and to a very small degree, proteins and fats. During ripening, fruits decrease in acidity and starch and increase in sugars. Juices are products for direct consumption and are obtained by the extraction of cellular juice from fruit; this operation can be done by pressing or by diffusion.

The fruit juice consumption has been associated with a healthful diet. Beyond its nutritional potential, these juices contain different compounds that show biological activities. Currently, the interest on phenolic compounds lies in its antioxidant capacity, which contributes to the protection of the harmful effects of oxidation stress on human health.

USE OF ENZYMES IN FRUIT JUICE PROCESSING

The presence of enzymes in food is very common, with oxidoreductases and hydrolases being the most important ones. In the oxidoreductase group, the enzymes that are of interest for the food industry are phenolases, peroxidases, catalases, peroxidases, and lipoxygenases. The use of enzymes in food processing is one of the greatest impacts of biotechnology on the sector. Hydrolases and oxirecdutases are the most popular enzyme groups in the food industry and are involved in new product development and in the development and enhancing of organoleptic characteristics (aroma, flavour, and colour) and in increasing yield.

There are mainly two groups of enzyme which are used in fruit juice industry i.e. pectinases and amylases. Amylases are very important biotechnologically with applications in industries such as textile, pulp and paper, leather, detergents, beer, spirits, bread production, cereals for children, starch liquefaction and saccharification, animal feed, and the chemical⁄pharmaceutical industry. From 1970 onwards the juice industry started to process edible fruits in large quantities; such fruits are picked while unripe and stored for relatively long periods of time at low temperature. Under these conditions, fruit pulp contains starch in sufficient amounts to cause turbidity or even gelatinise during processing, which makes productive procedures difficult. For this reason, the demand for amylolytic enzymes, especially glucoamylase has increased in the sector.

Pectinase was one of the first enzymes to be used and commercially applied for the processing of juices and wines. Its usage in the juice industry is related to a number of factors, especially in the clarification, maceration, and extraction, stabilisation of the juice colour during storage and increased yield. Currently, these enzymes account for approximately 20% of the worldwide enzyme market and are naturally produced by plants, fungi, yeast, and bacteria. These enzymes cause the degradation of long, complex molecules called pectin; today they have a key role in the juice industry. Pectinases are classified into three groups, according to the following criteria: Hydrolytic (hydrolases) or trans eliminative (lyases) cleavage of the glycosidic bonds; endo (randomic) or exo (from the molecule end) mechanism of action and preference for substrates, pectic acid or pectin. The three main types of pectinases are pectinesterase, depolymerising enzymes, and protopectinase.

In addition to pectinases, other enzymes such as hemicellulases and cellulase are used in the production of fruit juices, with the objective of optimising the processing of these products. These enzymes are part of maceration enzymes acting on soluble pectin hydrolysis and on cell wall components, lower viscosity, and maintenance of texture.

The enzymatic liquefaction technology is used to degrade cell wall polysaccharides, thereby releasing soluble compounds, especially the D-galacturonic acid and neutral sugars. In pulp liquefaction, pectin and cellulose hydrolysis are due to the activity of polygalacturonases, pectin lyases, pectinesterases, and cellulases. Upon the effect of these enzymes on the cell wall, neutral sugars such as D-arabinose, D-galactose, L-rhamnose, and D-xylose, which are bound to pectic substances, are released and become soluble.

Effect of Enzymatic Treatment on Juice Yield and Juice Clarification

High juice yield is an important goal for juice manufacture. Many modern processes for fruit and vegetable juice production employ enzymes as important processing aids to obtain higher yields and clarity. The use of maceration enzymes increases extraction yield and improves processing without extra costs. These enzymes are used after the cut of the raw material, in order to macerate the pulp to total or partial fruit liquefaction, thereby decreasing processing time and improving the extraction of fruit components. Upon the extraction, pectinases are added for clarification and decreased viscosity in order to facilitate filtration and concentration.

Removal Of Bitterness From Juice

The phenomenon of late bitterness in some citrus fruit juices represents an important economic hindrance for citriculture worldwide, especially in connection with consumer acceptance. The bitter taste is mainly attributed to the formation of limonin, a highly oxygenated derivative of triterpene (a compound of a furan and an epoxide group) and belongs to the class of limonoids.

The application of microorganisms as a tool to convert bitter citrus juices into non-bitter products requires enzymes of bacterial cells that are capable of metabolising limonin. Limonoate dehydrogenase is an enzyme that can be found in a number of species of microorganisms and can prevent the formation of limonin as it catalyses the oxidation of limonite A-ring lactone, 17-dehydrolimonoate, a non-bitter derivative that cannot be converted into limonin. Limonoate dehydrogenase can be isolated from Arthrobacter globiformis, Pseudomonas sp. strains, and from Rhodococcus fascians drolimonoate, a non-bitter derivative that cannot be converted into limonin.

Enzymes in fruit juice are very beneficial to the fruit juice industry. Their use results in higher yield of fruit juice and improves physical quality characteristics such as clarity, viscosity, filterability, colour etc. Enzymatic extraction of juices adds nutraceutical nutrition and improves organoleptic properties that reduce bitterness and prevents darkening of juices.

Summarize this Article with AI

Summarize this Article with AI