Enzyme Engineering And Its Application

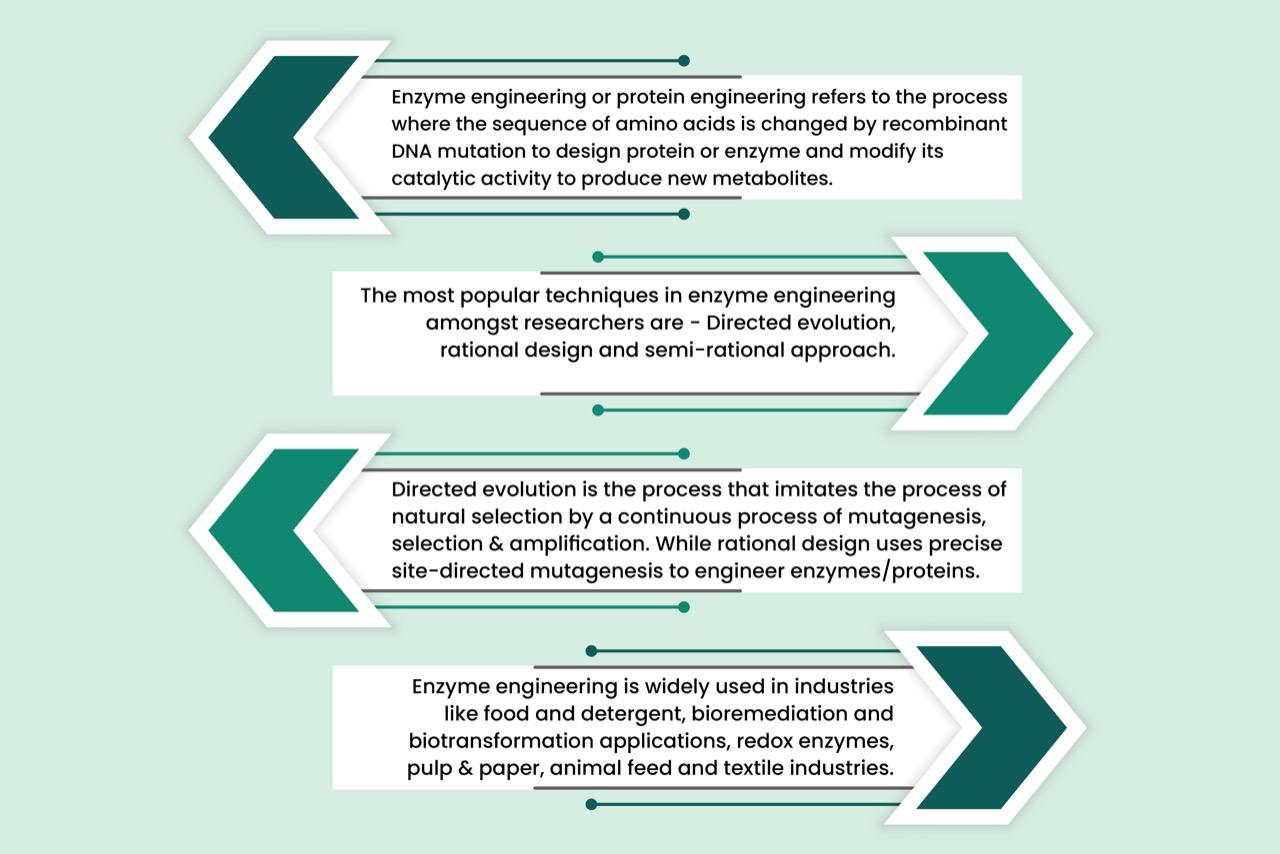

Enzyme engineering or protein engineering can be defined as the process through which the sequence of amino acids is changed by recombinant DNA mutation to design proteins or enzymes. This is done to modify the catalytic activity of single enzymes so that new metabolites can be produced. It also ensures that a new pathway is formed for reactions to occur. An enzyme reactor is used to carry out the altering in the amino acid sequence. The reactor contains a vessel which has a reactional medium. The two methods that are used are called directed evolution and rational design. These techniques are used during the process of drug discovery.

Directed evolution is the process that imitates the process of natural selection to lead nucleic acids or proteins to a goal desired by the researcher. This is done by subjecting genes to a continuous process of mutagenesis, selection and amplification. This process can be performed both in vivo (inside of living organisms) or in vitro (in cells or free solution). The advantage that it has over rational design sis that rational design requires an intensive knowledge of the protein structure. It also requires catalytic motivation. The sequence of amino acids is altered by site-directed mutagenesis so that the function of the protein changes. However, with rational design, even if the mechanism and structure of the protein are known, it is difficult to predict if the change is through mutation. Hence the advantage that directed evolution has is that it does not require and in-depth understanding of the mechanism and structure of the proteins or the effect of the mutations. A disadvantage of directed evolution is that the assay required should be in a large amount so that the effects of a large number of random mutations can be measured. Hence extensive research and development are required before directed evolution is carried out and since these assays are extremely specific, they cannot be used for new and different experiments. An advantage of the rational design is that it is inexpensive and technically easy. A different method has been especially popular with researchers. This method combines both these two techniques and is called a semi-rational approach. Directed evolutions aid protein engineering by improving the stability of proteins in high temperatures or harsh solvents, enhancing the binding affinities of therapeutic antibodies and changing the substrate specificity of pre-existing enzymes.

The applications of enzyme engineering:

Enzyme engineering is used in a variety of industries and these applications will be discussed below.

1. Food And Detergent Industries:

Back in 1993, the enzymes used in the food industry were used as examples to illustrate the importance of protein engineering as it could improve the important properties of these enzymes. The properties of enzymes involve thermostability, catalytic efficiency and specificity. One area in which the food industry uses enzyme engineering is the production and design of new enzymes to make new food ingredients. Another important application of enzyme engineering is the engineering of wheat and gluten proteins. Additionally, the food industry uses a variety of food processing enzymes, for example, amylases and lipases. The properties of these enzymes are improved by the process of recombinant DNA technology and enzyme engineering. Since enzymes like amylases, lipases and proteases have applications in many industries like the food and detergent industry, the enzyme engineering of these enzymes is beneficial to both industries. For example, proteases are important in the food industry regarding flavours, low-allergenic infant milk formulas and milk clotting. Similarly, in the detergent industry, proteases are used for removing protein stains. Hence industries can benefit if enzyme properties like having high activity at an alkaline pH or in low temperature, or improved stability at high temperatures are improved through enzyme engineering. Protein engineering uses methods like cold adaptation of a mesophilic subtilisin-like protease using directed evolution and DNA shuffling to isolate proteases with improved properties. The detergent industry is particularly interested in bacterial alkaline proteases. Enzyme engineering has helped them improve the stability and catalytic efficiency of the enzyme in high temperatures, alterations in washing conditions and oxidation.

2. Environmental Applications:

Enzyme engineering is also extremely important in the environmental industry. Enzyme and cell applications in the environmental industry are used for biosensors. Protein engineering has also been implicated to improve the microbial processes as microbial strains and their enzymes are important in the bioremediation and biotransformation processes. Two enzymes, in particular, were studied to improve their enzymatic activity i.e. molybdenum hydroxylases (the enzymes that catalyse the bacterial hydroxylation of N-heteroaromatic compound) and ring-opening 2, 4-dioxygenases help in bacterial quinaldine degradation. The enzymatic property of oxidative enzymes like peroxidases and laccases is also improved through enzyme engineering as they are a crucial treatment for organic pollutants. This is because they have a broad substrate specificity and can catalyse the oxidation od many different toxic organic pollutants. The properties of oxidative enzymes that are improved are enzyme denaturation due to organic solvents, the low reaction rate of laccases and toxicity of mediators. Petroleum biorefining is another application of enzyme engineering in the environmental industry. Enzyme engineering can be done to design new biocatalysts that are required in petroleum biorefining. Recent omic technologies have also been implicated in the applications of protein engineering in the environmental industry. This is because metagenomic libraries can help determine and analyse genetic resources of complex microbial communities which can consequently help identify microbial enzymatic diversity. This can lead to contributions to decrease in the pollutant burdens, advances in renewable energy sources, and process energies. Protein engineering can also help the biodegradation of aromatic compounds such as benzene and toluene.

3. Applications With Redox Enzymes:

Enzyme engineering is also essential in the improvement of redox proteins and enzymes. These enzymes can be altered so that they can be used in nanodevices for biosensing as well as in nanobiotechnology. Enzyme engineering using directed evolution, rational resign or a combination of both is used in bioelectrocatalysis. It also helps in the design of new nucleic acid-based catalysis construction and intramolecular electron transfer network remodelling. The cytochrome P450 family fo enzymes like heme monooxygenases that are used for biosynthesis and biodegradation of metabolic compounds can also be improved through enzyme engineering.

4. Applications With Industrially Important Enzymes:

The enzyme engineering of industrially important enzymes such as nitrilases, aldolases, microbial beta D-xylosidases etc is also an important application. While nitrilases are important for biotransformation; their enzymatic properties require improvement for higher industrial processes. As a result, New enzymes are screened from novel isolates and mediums and enzyme engineering was applied. Alodolases are implicated in stereoselective synthesis reactions in the carbon-carbon bond formation. Enzyme engineering and screening methods aid in improving enzymes for such processes. In the baking and animal-feeding industry, as well as deinking recycled paper, microbial bata D-xylosidases are also important. These enzymes are used for the catalysing hydrolysis of non-reducing end xylose residues from xylooligosaccharides. Therefore, they can be implicated in the hydrolysis of lignocellulosic biomass in biofuel fermentation to produce ethanol and butanol. Hence improving their enzymatic properties can be important for many industries. Furthermore, the enzymatic engineering of organic solvent tolerant enzymes is also important as using organic solvents is essential for industrial processes but adversely affects enzyme activity.

These industrial applications of enzyme engineering prove just how important it is and how further research should be dedicated to making the process better. Apart from these industries enzyme engineering can also be used enzymatic biofuel cell design. This is because getting biofuels from lignocellulosic resources is difficult because the enzyme hydrolysis efficiency of lignocellulose is low which leads to an increase in the cost of biofuels. Enzyme engineering can help improve the performance of lignocellulose to produce the desired effect. This concludes the list of the applications enzyme engineering. While this is a comprehensive list is not an exhaustive list as it is used in the industry for varied reasons.

Summarize this Article with AI

Summarize this Article with AI