Applications of Enzymes in Sugar

Applications of Enzymes in Sugar

Generally, enzymes are not ingredients but are present in several other ingredients, mainly in flour and yeast. When we understand how enzymes work, it is useful in understanding the process of fermentation.

Enzymes are as exclusive as our fingerprints. They are defined as minute substances that are produced by living organisms that speed up or bring about a chemical change. A great example of this is the enzymes in our digestive tract that break down food particles. Enzyme action is specific and every class of enzymes has just one specific chemical conversion which it brings about.

For instance, one type of sugar enzymes converts sugar into alcohol and carbon dioxide. This is the only function that this enzyme can perform.

Application of Enzymes in the sugar processing industry:

Mixed juice in sugar mills has a high content of starch. This generally leads to a reduction in the boiling house efficiency, poor mud filtration, as well as an increase in the formation of molasses. Hence, sucrose tends to lose in the raw sugar factory. An enzyme dextranase helps in the decomposition of dextran which is synthesized by the microorganisms.

The sugar juice then has a lesser viscosity and there is an improvement in the process of clarification. During this processing time, dextranase helps in the increase in crystallisation of sugar. This helps in the prevention of dextran-forming flocs and hence, helps in enhancing the overall quality of refined sugar.

Sugar processing enzymes in the sugar and starch industry:

Starch is a polysaccharide that is present in plant organs. Of course, it is the second most abundant compound which is synthesized by the plants, cellulose is the first and is found in the granular form. These granules get deposited in the form of a reserve food supply that is used during growth, dormancy or germination.

The shape and size of the starch granules tend to vary depending on the source of starch. The commercial sources of starch are generally the storage plant organs like the seeds of cereal grains (wheat, rice, corn, and sorghum), tubers (potato), and roots (tapioca).

The primary process of starch refining includes physical processes in which starch is produced in a suspension and is free of other matter like proteins, sugar and fibres, and has a typical purity of 99%. Most of the starches consist of two kinds of glucose polymers. The first one is generally a linear molecule that consists of glucose residues linked known as amylose, and the second one being a branched polymer that, additionally, consists of branch points, known as

amylopectin.

Both these fractions occur in varying proportions in starches from several different kinds of sources and contribute to their different chemical and physical properties. Generally, amylose is present in the smaller proportion, which consists of 15-30% of the most common starches, although, when they are specially bred, the waxy starches do not contain amylose.

On the other hand, amylomaize starch consists of 50 to 80% amylose depending on the variety. Starch is synthesized in the plants from the sugars produced, and in turn, from carbon dioxide and water during the process of photosynthesis. When it comes to the different chemicals used in sugar processing the actual mechanism of the build-up of starch is not entirely understood.

However, it is clear that several sugar enzymes are involved in the process which are starch synthase, phosphorylase, and branching enzymes. Linear chains get produced from the glucose through the action of the first two enzymes. Branch points get inserted into the

molecules growing via the branching enzymes. Starch granules get formed around a central nucleus which is formed by the deposition of a small amount of insoluble material. As the material gets added to the nucleus, the shape is initially spherical but then becomes elongated or flattened.

Enzymes application in sugar processing:

Polysaccharides are known as long-chain molecules of simple sugar that are linked together, either in a straight or branched form, but in a specific pattern. They are found in sugarcane and are derived from two different sources. The first one is starch and the other is dextran. The commercial starch processing of monosaccharides as well as oligosaccharides is dependent on how these three major enzymes are available: dextranase, glucoamylase, and alpha-amylase. All these enzymes possess their unique set of optimum temperature and pH for usage.

Hence, the unit operations of a starch plant tend to follow the different operational conditions when it comes to each individual enzymatic step. Sugar enzymes help in accelerating the conversion of sugar to glucose. This conversion process of application of enzymes in sugar occurs through several processes like saccharification and liquefaction. The sugarcane plant consists of several polysaccharides. Cellulose and hemicelluloses that are present in the cell wall offer structural strength to the cane plant.

Since they are not soluble in water, they generally do not affect the manufacturing process of sugar. Starch, which brings about changes in the metabolic activity of a growing plant typically happens in sugarcane in the form of an insoluble granule. These granules tend to dissolve during starch processing and hence, have affected the whole manufacturing process. Other

polysaccharides like dextran and glucan have also been detected in the sugarcane plant.

Chemicals used in sugar manufacturing process where the enzymes present in flour are :

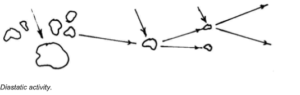

1. Diastase/amylase

Under the right kind of conditions, diastase breaks up some starch, liquefies it and converts it to malt sugar. This provides food for both sugars and yeast which helps the loaf to turn brown upon baking. It is a crucial function when it comes to lean dough wherein almost little or no sugar gets added. Amylase or diastase gets destroyed at 77°C (170°F) during the process of

baking, a point at which the dough stops to expand.

One of the laboratory tasks at the flour mill is to find out if the grain has the right amount of enzyme balance. Either too many or too few enzymes affects the fermentation and handling of the dough. One such problem in which too many sugar enzymes are present is much evident in the rye flour wherein the starch’s integrity is especially crucial.

The amount of diastase present in the grains varies from one year to the other depending on the conditions of the harvest. During the damp harvest season, the grain starts to sprout which acts as a signal for the enzymes to become active. The starch from these kinds of grains is known to be damaged, which is generally not a bad thing since some amount of damaged starch provides yeast with food. The miller tends to adjust this level in case it is necessary by adding amylase and blending the flour.

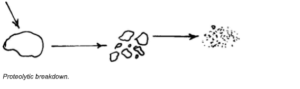

2. Protease

Protease is generally found in flour but is also present in yeast and malt. It converts a part of protein that does not dissolve in water into a different form that dissolves in water. Under this condition, the protein is available to be used as food by the yeast. This protein makes gluten more elastic when it softens it and gives amino acids.

The protease starts working immediately once the dough gets mixed. It is important since it imparts good flavouring and digestibility to the bread baked.

Enzymes present in yeast:

When it comes to the chemicals used in sugar industry, the enzymes which are present in yeast include maltase and invertase. Additionally, there are many other minor enzymes present in yeast, each of which contributing in one way or the other to bring about the changes in the yeast activity in the dough. Some of these changes help in imparting flavour as well as digestibility to the finished bread.

1. Maltase

Maltase changes maltose or malt sugar into simple sugar.

2. Invertase

Invertase converts cane sugar into simple sugar. This enzyme only works if the granulated cane sugar gets added to the dough. For example, it doesn’t break down maltose.

3. Zymase

Zymase works on simple sugars which are produced by the action of maltase and invertase.

Zymase tends to change simple sugars into carbon dioxide and alcohol that make the dough rise and expand.

To summarizing, enzymes tend to work in the fermented dough for affecting sugar production and starch reduction. This helps in enabling the yeast to thrive and generate carbon dioxide that leavens bread. Every enzyme has a specific job to perform. The enzyme level gets checked at the mill laboratory and the flour which is delivered to the baker gets perfectly balanced with the right amount for a reliable fermentation.

ALPHA AMYLASE FOR HYDROLYZING STARCH

Our Alpha Amylase Enzyme hydrolyses starch to increase sugar recovery and improve overall performance.

Reduce Dextran

Levels

Reduces Crystal

Elongation

Reduces Water

Consumption

DEXTRANASE ENZYME FOR HYDROLYSING DEXTRAN

Our dextranase Enzyme hydrolyses Dextran to increase sugar recovery and improve overall performance.

Reduces Syrup

Viscosity

Better Quality

Sugar

Reduces Steam

Consumption

INVERTASE

Our invertase enzyme hydrolyses the terminal non-reducing beta-fructofuranoside residues in beta-fructofuranosides releasing invert sugar.

Complete inversion

Lower dosage

No side products/impurities formation

Related Articles

Making Sugar Processing Sweet: Boosting Efficiency with Enzymes

In the world of sugar processing, efficiency is key. The ability to produce high yields of sugar while minimizing energy consumption and costs can make a significant difference in the success and profitability of a processing plant. One way to achieve this efficiency...

The Role of Enzymes in Sugar Processing: Enhancing Efficiency and Quality

Sugar processing plays a vital role in our daily lives, as sugar is an essential ingredient used in various food and beverage products. The process of turning raw materials, such as sugar cane or sugar beets, into the refined sugar we consume involves complex steps...

Applications of Enzymes in Sugar

Applications of Enzymes in Sugar

Generally, enzymes are not ingredients but are present in several other ingredients, mainly in flour and yeast. When we understand how enzymes work, it is useful in understanding the process of fermentation.

Enzymes are as exclusive as our fingerprints. They are defined as minute substances that are produced by living organisms that speed up or bring about a chemical change. A great example of this is the enzymes in our digestive tract that break down food particles. Enzyme action is specific and every class of enzymes has just one specific chemical conversion which it brings about.

For instance, one type of sugar enzymes converts sugar into alcohol and carbon dioxide. This is the only function that this enzyme can perform.

Application of Enzymes in the sugar processing industry:

Mixed juice in sugar mills has a high content of starch. This generally leads to a reduction in the boiling house efficiency, poor mud filtration, as well as an increase in the formation of molasses. Hence, sucrose tends to lose in the raw sugar factory. An enzyme dextranase helps in the decomposition of dextran which is synthesized by the microorganisms.

The sugar juice then has a lesser viscosity and there is an improvement in the process of clarification. During this processing time, dextranase helps in the increase in crystallisation of sugar. This helps in the prevention of dextran-forming flocs and hence, helps in enhancing the overall quality of refined sugar.

Sugar processing enzymes in the sugar and starch industry:

Starch is a polysaccharide that is present in plant organs. Of course, it is the second most abundant compound which is synthesized by the plants, cellulose is the first and is found in the granular form. These granules get deposited in the form of a reserve food supply that is used during growth, dormancy or germination.

The shape and size of the starch granules tend to vary depending on the source of starch. The commercial sources of starch are generally the storage plant organs like the seeds of cereal grains (wheat, rice, corn, and sorghum), tubers (potato), and roots (tapioca).

The primary process of starch refining includes physical processes in which starch is produced in a suspension and is free of other matter like proteins, sugar and fibres, and has a typical purity of 99%. Most of the starches consist of two kinds of glucose polymers. The first one is generally a linear molecule that consists of glucose residues linked known as amylose, and the second one being a branched polymer that, additionally, consists of branch points, known as

amylopectin.

Both these fractions occur in varying proportions in starches from several different kinds of sources and contribute to their different chemical and physical properties. Generally, amylose is present in the smaller proportion, which consists of 15-30% of the most common starches, although, when they are specially bred, the waxy starches do not contain amylose.

On the other hand, amylomaize starch consists of 50 to 80% amylose depending on the variety. Starch is synthesized in the plants from the sugars produced, and in turn, from carbon dioxide and water during the process of photosynthesis. When it comes to the different chemicals used in sugar processing the actual mechanism of the build-up of starch is not entirely understood.

However, it is clear that several sugar enzymes are involved in the process which are starch synthase, phosphorylase, and branching enzymes. Linear chains get produced from the glucose through the action of the first two enzymes. Branch points get inserted into the

molecules growing via the branching enzymes. Starch granules get formed around a central nucleus which is formed by the deposition of a small amount of insoluble material. As the material gets added to the nucleus, the shape is initially spherical but then becomes elongated or flattened.

Enzymes application in sugar processing:

Polysaccharides are known as long-chain molecules of simple sugar that are linked together, either in a straight or branched form, but in a specific pattern. They are found in sugarcane and are derived from two different sources. The first one is starch and the other is dextran. The commercial starch processing of monosaccharides as well as oligosaccharides is dependent on how these three major enzymes are available: dextranase, glucoamylase, and alpha-amylase. All these enzymes possess their unique set of optimum temperature and pH for usage.

Hence, the unit operations of a starch plant tend to follow the different operational conditions when it comes to each individual enzymatic step. Sugar enzymes help in accelerating the conversion of sugar to glucose. This conversion process of application of enzymes in sugar occurs through several processes like saccharification and liquefaction. The sugarcane plant consists of several polysaccharides. Cellulose and hemicelluloses that are present in the cell wall offer structural strength to the cane plant.

Since they are not soluble in water, they generally do not affect the manufacturing process of sugar. Starch, which brings about changes in the metabolic activity of a growing plant typically happens in sugarcane in the form of an insoluble granule. These granules tend to dissolve during starch processing and hence, have affected the whole manufacturing process. Other

polysaccharides like dextran and glucan have also been detected in the sugarcane plant.

Chemicals used in sugar manufacturing process where the enzymes present in flour are :

1. Diastase/amylase

Under the right kind of conditions, diastase breaks up some starch, liquefies it and converts it to malt sugar. This provides food for both sugars and yeast which helps the loaf to turn brown upon baking. It is a crucial function when it comes to lean dough wherein almost little or no sugar gets added. Amylase or diastase gets destroyed at 77°C (170°F) during the process of

baking, a point at which the dough stops to expand.

One of the laboratory tasks at the flour mill is to find out if the grain has the right amount of enzyme balance. Either too many or too few enzymes affects the fermentation and handling of the dough. One such problem in which too many sugar enzymes are present is much evident in the rye flour wherein the starch’s integrity is especially crucial.

The amount of diastase present in the grains varies from one year to the other depending on the conditions of the harvest. During the damp harvest season, the grain starts to sprout which acts as a signal for the enzymes to become active. The starch from these kinds of grains is known to be damaged, which is generally not a bad thing since some amount of damaged starch provides yeast with food. The miller tends to adjust this level in case it is necessary by adding amylase and blending the flour.

2. Protease

Protease is generally found in flour but is also present in yeast and malt. It converts a part of protein that does not dissolve in water into a different form that dissolves in water. Under this condition, the protein is available to be used as food by the yeast. This protein makes gluten more elastic when it softens it and gives amino acids.

The protease starts working immediately once the dough gets mixed. It is important since it imparts good flavouring and digestibility to the bread baked.

Enzymes present in yeast:

When it comes to the chemicals used in sugar industry, the enzymes which are present in yeast include maltase and invertase. Additionally, there are many other minor enzymes present in yeast, each of which contributing in one way or the other to bring about the changes in the yeast activity in the dough. Some of these changes help in imparting flavour as well as digestibility to the finished bread.

1. Maltase

Maltase changes maltose or malt sugar into simple sugar.

2. Invertase

Invertase converts cane sugar into simple sugar. This enzyme only works if the granulated cane sugar gets added to the dough. For example, it doesn’t break down maltose.

3. Zymase

Zymase works on simple sugars which are produced by the action of maltase and invertase.

Zymase tends to change simple sugars into carbon dioxide and alcohol that make the dough rise and expand.

To summarizing, enzymes tend to work in the fermented dough for affecting sugar production and starch reduction. This helps in enabling the yeast to thrive and generate carbon dioxide that leavens bread. Every enzyme has a specific job to perform. The enzyme level gets checked at the mill laboratory and the flour which is delivered to the baker gets perfectly balanced with the right amount for a reliable fermentation.

0 Comments

Submit a Comment

You must be logged in to post a comment.

ALPHA AMYLASE FOR HYDROLYZING STARCH

Our Alpha Amylase Enzyme hydrolyses starch to increase sugar recovery and improve overall performance.

Reduces Syrup Viscosity

Better Quality Sugar

Reduces Steam Consumption

DEXTRANASE ENZYME FOR HYDROLYSING DEXTRAN

Our dextranase Enzyme hydrolyses Dextran to increase sugar recovery and improve overall performance.

Reduce Dextran Levels

Reduces Crystal Elongation

Reduces Water Consumption

INVERTASE

Our invertase enzyme hydrolyses the terminal non-reducing beta-fructofuranoside residues in beta-fructofuranosides releasing invert sugar.

Complete inversion

Lower dosage

No side products/impurities formation

Making Sugar Processing Sweet: Boosting Efficiency with Enzymes

In the world of sugar processing, efficiency is key. The ability to produce high yields of sugar while minimizing energy consumption and costs can make a significant difference in the success and profitability of a processing plant. One way to achieve this efficiency...

The Role of Enzymes in Sugar Processing: Enhancing Efficiency and Quality

Sugar processing plays a vital role in our daily lives, as sugar is an essential ingredient used in various food and beverage products. The process of turning raw materials, such as sugar cane or sugar beets, into the refined sugar we consume involves complex steps...

Applications Of Dextranase Enzyme

Dextranase enzyme is used for the degradation of dextran into smaller fractions of low molecular weight giving dextranase great commercial and clinical importance. Dextran is a collective word used for dextran hydrolase and dextranase. Dextranase is easily soluble in...

0 Comments