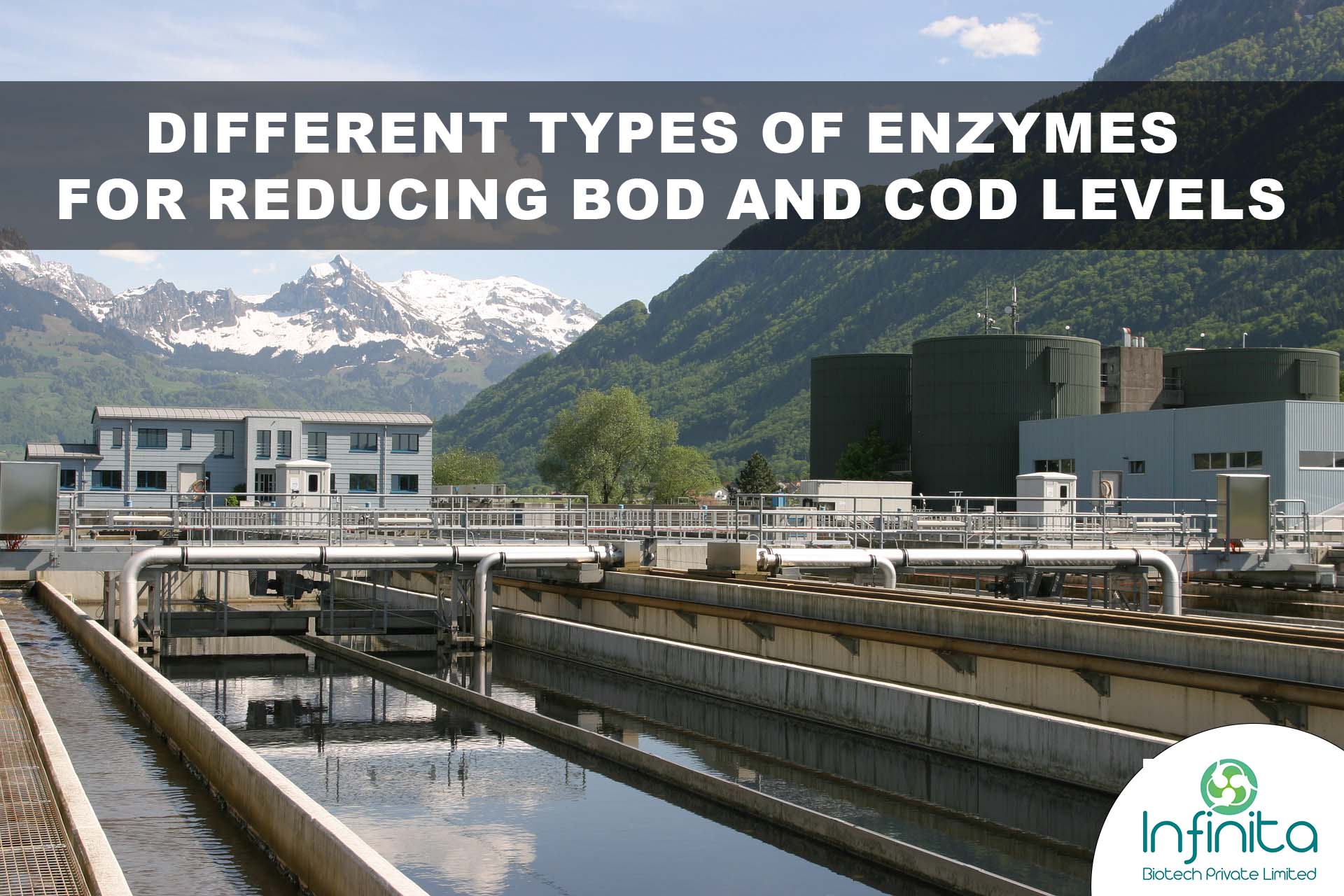

What Are The Different Types of Enzymes for Reducing BOD and COD Levels?

It is a common misconception that water doesn’t have oxygen. In reality, water does contain oxygen – in dissolved form. Going back to the chemistry class, the chemical formula of water is H2O, where H is hydrogen and O stands for oxygen. Though oxygen isn’t a significant element of water, it is crucial for marine life, whatever minor percentage there is. Water contains thousands and hundreds of bacteria and microorganisms; these organisms consume dissolved oxygen while decomposing the organic matter.

Now, if these organisms consume more oxygen, it will increase the fatality rate of marine life. This is why it is very important to test the water for its oxygen consumption level. During water testing, if this level of oxygen consumption is high, then water treatment is needed, for which there are various ways, for instance, enzymatic water treatment.

Before we move on to enzymes, let’s first get a clear picture of the two oxygen consumption levels, BOD and COD, are.

What Are BOD and COD Levels?

BOD stands for Biological Oxygen Demand, and it represents the oxygen consumed by the microorganisms and bacteria to decompose organic matter under the biological reaction – aerobic process. The water test is pretty simple for BOD; all you have to do is put some sample water in a bottle and leave it under certain weather conditions for a duration of five days. In comparison to COD, the value for BOD is low, as it is used for wasting loading in treatment plants.

On the other hand, COD stands for Chemical Oxygen Demand, and it represents the consumption of dissolved oxygen used in the oxidation process to oxidise chemical materials, like petroleum. This level is used to curb the short term effects. The test of COD level is similar to that of BOD, but instead of leaving it naturally, a potent oxidising agent is used with the water sample. This level is used to determine the effects of effluent on water.

Why Choose Enzymatic Treatment For Reducing BOD and COD Level?

Pollution has been a serious concern for the longest time, especially water pollution. We only have 1% drinkable water, and if industries start dumping garbage in that, the level will soon go even below. Another huge disadvantage of water pollution is that it increases the BOD and COD levels. Furthermore, this sudden increase in BOD and COD can significantly increase the death rate of aquatic life, which will affect humans as well. While there are a number of ways to treat water, enzymatic wastewater treatment is considered to be the best. Mentioned below is the list of benefits to prove why enzymatic wastewater treatment is best for reducing BOD and COD.

- Pollutants in wastewater undergo biological processes.

- Pollutant transformation reduces water toxicity.

- Because they are naturally biodegradable, they contribute to a more sustainable environment.

- Its usage does not need the employment of high-pressure, high-heat, or corrosion-resistant equipment, which saves money and energy.

- In a variety of sectors, they can be used to replace or minimise the usage of polluting chemicals.

Living creatures are used to make them. Furthermore, contemporary molecular biology techniques enable the development of novel enzymes and application sectors, as well as the improvement of production processes.

Enzymes are pretty particular about the substrates they’ll react with.

Wastewater Treatment

The Garbage enzyme, produced by using garbage organic waste of vegetables, etc, is used to reduce BOD and COD levels. These enzymes can be easily produced by fermenting the waste from fruits and vegetables. Food waste makes up a substantial component of municipal solid waste. Thus, this alternative approach of biological recovery of organic waste might be a solution for waste minimisation and reduction. The use of garbage enzymes is an efficient wastewater treatment technology and is in accordance with the ecosystem.

Organic wastes are plentiful and molasses or brown sugar is readily available at a cheap cost making wastewater treatment using garbage enzymes extremely cost-effective when compared to traditional wastewater treatment. Only once the BOD levels of the enzyme solution are reduced is wastewater treatment using garbage enzyme solution shown to be successful.

Hydrogen peroxide, often linked with cleaning, is another common chemical used for wastewater treatment. In wastewater treatment, its work is similar as well. Hydrogen Peroxide (H2O2) is a chemical enzyme and is a little more expensive than biological and physical methods. It has been used to treat wastewater for many years and is still one of the most effective ways.

Hydrogen peroxide is often considered when the water has high levels of toxic compounds like pesticides, resins, coolants, dyestuffs, etc. It can be used alone or along with more catalysts like iron and ozone or alkali. H2O2 can easily oxidise BOD and COD. As a result, these levels are decreased in water. It is not a long term method but is very effective, especially where the water has a high concentration of toxic elements.

Natural Enzymes From Waste

Natural enzymes produced from waste are one of the most efficient ways of wastewater treatment. Protein compounds, known as eco enzymes (natural enzymes) speed up chemical reactions. They perform the function of biological catalysts. When compared to traditional catalysts, eco enzymes have advantages that make them more effective. Because they’re named Eco enzymes, these enzymes almost don’t cause any disposal issues and they reduce BOD and COD levels.

Infinita Biotech manufactures, markets, and develops unique enzyme compositions for a variety of specialised sectors. We are recognised by the Department of Scientific and Industrial Research, the Ministry of Science and Technology, and the Government of India. Our aim is to produce eco-friendly enzymatic solutions for different industries like Distillery, Sugar, Brewery, Starch, Wine, Malt, Wastewater Treatment, Food, Animal Feed, Agriculture, Cellulosic Ethanol, Biodiesel, and many others.

ENZYMES FOR REDUCING BOD AND COD LEVEL

Our customized enzyme based Formulation can be used for the aerobic stage of the process.

Eco-Friendly

Reduce Sludge

Volume

Faster Bacterial

Oxidation

ENZYMES FOR BIOGAS PRODUCTION

Our customised enzyme based formulation can be utilised for the anaerobic stage of the process.

Eco-Friendly

Increase In Biogas

Production

Increases Digestor

Efficiency

Enzymatic Process for Biodiesel and Biobased Material Production

Biodiesel as an alternative fuel is gaining demand all over the world due to environmental concerns and depletion of the traditional fossil fuel industry worldwide. But there were concerns like high economic cost in utilizing biodiesel process which can and has been...

Enzymatic Approach To Biodiesel Production

Enzymes In Biodiesel Production With fossil fuels getting extinct, there are alternative ways that are found by scientists and researchers to generate energy that is required to run the world. You must look for the energy sources from where the power can be produced...

What Are The Different Types of Enzymes for Reducing BOD and COD Levels?

It is a common misconception that water doesn’t have oxygen. In reality, water does contain oxygen – in dissolved form. Going back to the chemistry class, the chemical formula of water is H2O, where H is hydrogen and O stands for oxygen. Though oxygen isn’t a significant element of water, it is crucial for marine life, whatever minor percentage there is. Water contains thousands and hundreds of bacteria and microorganisms; these organisms consume dissolved oxygen while decomposing the organic matter.

Now, if these organisms consume more oxygen, it will increase the fatality rate of marine life. This is why it is very important to test the water for its oxygen consumption level. During water testing, if this level of oxygen consumption is high, then water treatment is needed, for which there are various ways, for instance, enzymatic water treatment.

Before we move on to enzymes, let’s first get a clear picture of the two oxygen consumption levels, BOD and COD, are.

What Are BOD and COD Levels?

BOD stands for Biological Oxygen Demand, and it represents the oxygen consumed by the microorganisms and bacteria to decompose organic matter under the biological reaction – aerobic process. The water test is pretty simple for BOD; all you have to do is put some sample water in a bottle and leave it under certain weather conditions for a duration of five days. In comparison to COD, the value for BOD is low, as it is used for wasting loading in treatment plants.

On the other hand, COD stands for Chemical Oxygen Demand, and it represents the consumption of dissolved oxygen used in the oxidation process to oxidise chemical materials, like petroleum. This level is used to curb the short term effects. The test of COD level is similar to that of BOD, but instead of leaving it naturally, a potent oxidising agent is used with the water sample. This level is used to determine the effects of effluent on water.

Why Choose Enzymatic Treatment For Reducing BOD and COD Level?

Pollution has been a serious concern for the longest time, especially water pollution. We only have 1% drinkable water, and if industries start dumping garbage in that, the level will soon go even below. Another huge disadvantage of water pollution is that it increases the BOD and COD levels. Furthermore, this sudden increase in BOD and COD can significantly increase the death rate of aquatic life, which will affect humans as well. While there are a number of ways to treat water, enzymatic wastewater treatment is considered to be the best. Mentioned below is the list of benefits to prove why enzymatic wastewater treatment is best for reducing BOD and COD.

- Pollutants in wastewater undergo biological processes.

- Pollutant transformation reduces water toxicity.

- Because they are naturally biodegradable, they contribute to a more sustainable environment.

- Its usage does not need the employment of high-pressure, high-heat, or corrosion-resistant equipment, which saves money and energy.

- In a variety of sectors, they can be used to replace or minimise the usage of polluting chemicals.

Living creatures are used to make them. Furthermore, contemporary molecular biology techniques enable the development of novel enzymes and application sectors, as well as the improvement of production processes.

Enzymes are pretty particular about the substrates they’ll react with.

Wastewater Treatment

The Garbage enzyme, produced by using garbage organic waste of vegetables, etc, is used to reduce BOD and COD levels. These enzymes can be easily produced by fermenting the waste from fruits and vegetables. Food waste makes up a substantial component of municipal solid waste. Thus, this alternative approach of biological recovery of organic waste might be a solution for waste minimisation and reduction. The use of garbage enzymes is an efficient wastewater treatment technology and is in accordance with the ecosystem.

Organic wastes are plentiful and molasses or brown sugar is readily available at a cheap cost making wastewater treatment using garbage enzymes extremely cost-effective when compared to traditional wastewater treatment. Only once the BOD levels of the enzyme solution are reduced is wastewater treatment using garbage enzyme solution shown to be successful.

Hydrogen peroxide, often linked with cleaning, is another common chemical used for wastewater treatment. In wastewater treatment, its work is similar as well. Hydrogen Peroxide (H2O2) is a chemical enzyme and is a little more expensive than biological and physical methods. It has been used to treat wastewater for many years and is still one of the most effective ways.

Hydrogen peroxide is often considered when the water has high levels of toxic compounds like pesticides, resins, coolants, dyestuffs, etc. It can be used alone or along with more catalysts like iron and ozone or alkali. H2O2 can easily oxidise BOD and COD. As a result, these levels are decreased in water. It is not a long term method but is very effective, especially where the water has a high concentration of toxic elements.

Natural Enzymes From Waste

Natural enzymes produced from waste are one of the most efficient ways of wastewater treatment. Protein compounds, known as eco enzymes (natural enzymes) speed up chemical reactions. They perform the function of biological catalysts. When compared to traditional catalysts, eco enzymes have advantages that make them more effective. Because they’re named Eco enzymes, these enzymes almost don’t cause any disposal issues and they reduce BOD and COD levels.

Infinita Biotech manufactures, markets, and develops unique enzyme compositions for a variety of specialised sectors. We are recognised by the Department of Scientific and Industrial Research, the Ministry of Science and Technology, and the Government of India. Our aim is to produce eco-friendly enzymatic solutions for different industries like Distillery, Sugar, Brewery, Starch, Wine, Malt, Wastewater Treatment, Food, Animal Feed, Agriculture, Cellulosic Ethanol, Biodiesel, and many others.

0 Comments

Submit a Comment

You must be logged in to post a comment.

ENZYMES FOR REDUCING BOD AND COD LEVEL

Our customized enzyme based Formulation can be used for the aerobic stage of the process.

Eco-Friendly

Reduce Sludge Volume

Faster Bacterial Oxidation

ENZYMES FOR BIOGAS PRODUCTION

Our customised enzyme based formulation can be utilised for the anaerobic stage of the process.

Eco-Friendly

Increase In Biogas Production

Increases Digestor Efficiency

Enzymatic Process for Biodiesel and Biobased Material Production

Biodiesel as an alternative fuel is gaining demand all over the world due to environmental concerns and depletion of the traditional fossil fuel industry worldwide. But there were concerns like high economic cost in utilizing biodiesel process which can and has been...

Enzymatic Approach To Biodiesel Production

Enzymes In Biodiesel Production With fossil fuels getting extinct, there are alternative ways that are found by scientists and researchers to generate energy that is required to run the world. You must look for the energy sources from where the power can be produced...

Which Enzymes Are Used In Biodiesel Production?

Enzymes Used In Biodiesel Production Fluid fuels have been utilized for a long time as the most predominant and fundamental fuel for engine motors. Be that as it may, depleting fossil fuel reserves, and the propensity for developing new sustainable biofuels, have...

0 Comments